In the fast-paced logistics industry, staying ahead requires innovation and efficiency. As the demand for timely deliveries and optimized routes continues to rise, AI-driven predictive analytics has emerged as a game-changer. In this blog post, we explore how logistics companies can harness the power of AI to streamline operations, reduce costs, and improve customer satisfaction. With the help of charts, graphs, and infographics, we illustrate the transformative potential of predictive analytics in logistics.

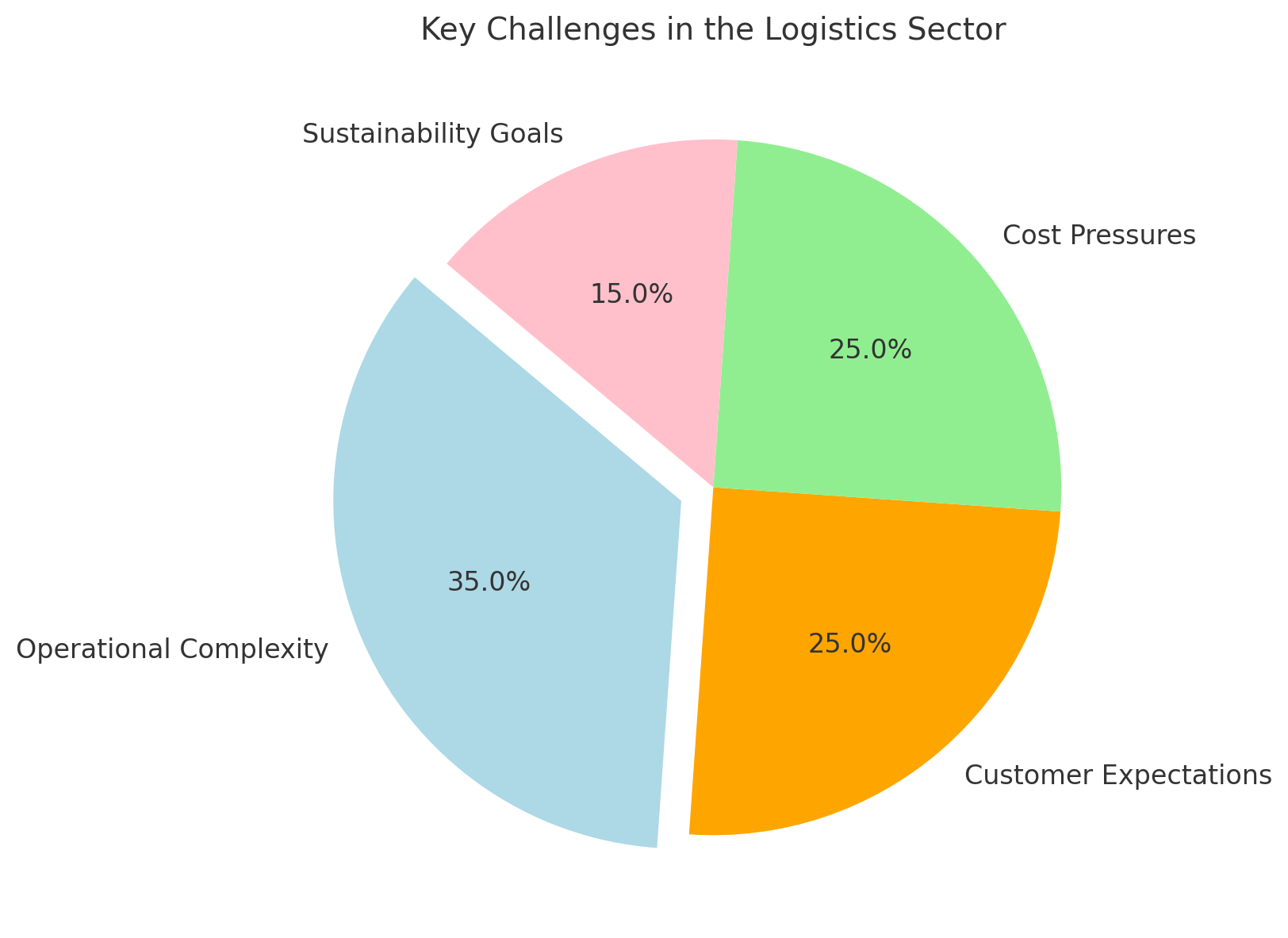

The Challenges Facing Modern Logistics

1. Increasing Operational Complexity

Managing large fleets, coordinating delivery schedules, and optimizing routes involve countless variables, making operations more complex.

2. Rising Customer Expectations

Customers now demand faster deliveries and real-time tracking, pushing logistics providers to adopt innovative solutions.

3. Cost Pressures

Fuel prices, maintenance costs, and labor shortages are putting pressure on profit margins.

4. Environmental Sustainability

Logistics companies face increasing pressure to reduce their carbon footprint while maintaining efficiency.

Why Predictive Analytics?

1. Improving Demand Forecasting

AI-driven models analyze historical data and market trends to predict demand fluctuations, enabling better resource allocation.

2. Optimizing Routes

Real-time traffic data and historical patterns help AI recommend the most efficient routes, reducing fuel consumption and delivery times.

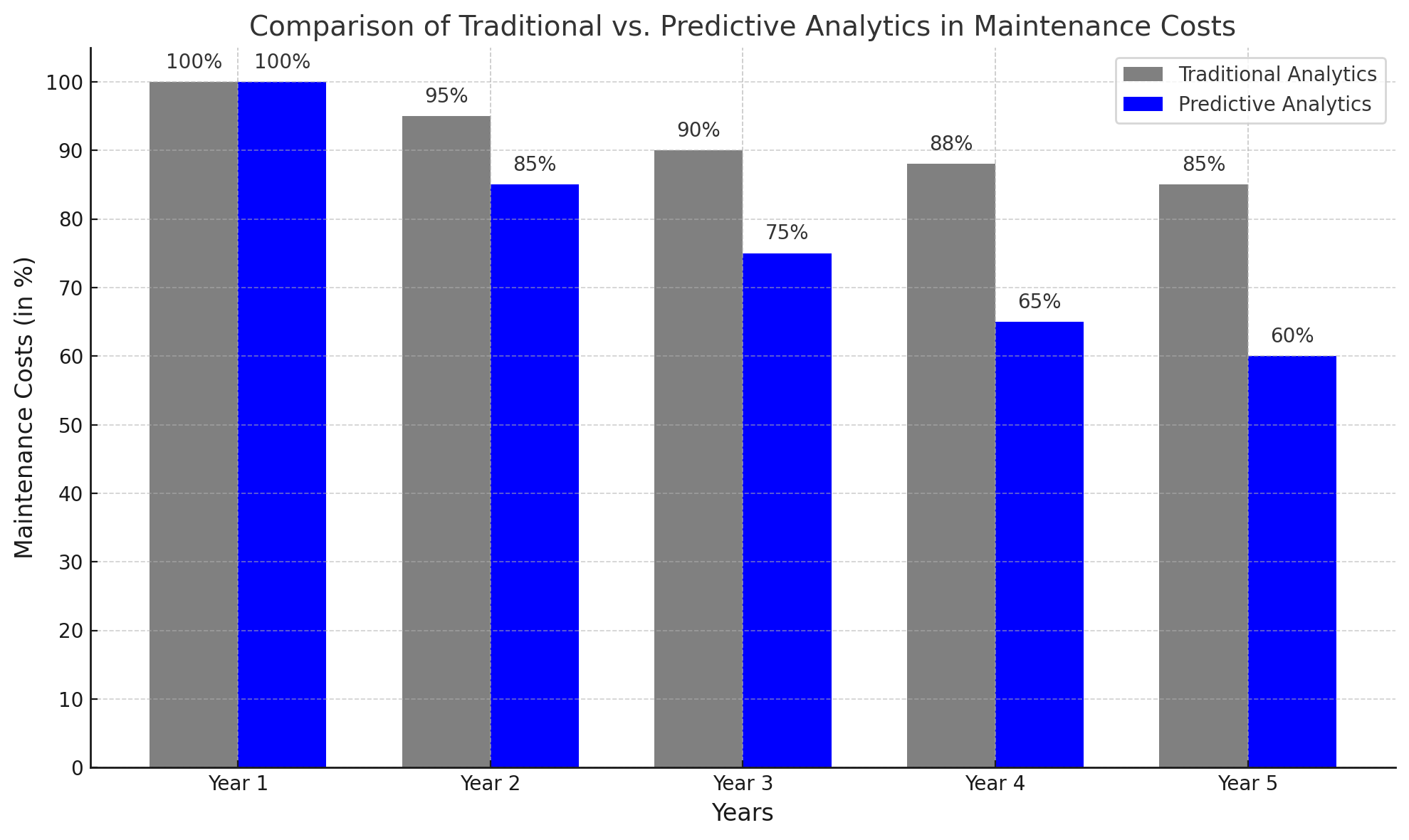

3. Reducing Maintenance Downtime

Predictive analytics identifies potential vehicle issues before they lead to breakdowns, minimizing downtime.

Key Applications of AI-Driven Predictive Analytics

1. Real-Time Fleet Management

- Monitor vehicle locations, fuel levels, and driver behavior in real time.

- Use AI to identify inefficiencies and suggest improvements.

2. Dynamic Pricing Models

- Adjust pricing based on demand forecasts and operational costs.

- Use predictive models to optimize profitability.

3. Inventory Optimization

- Predict stock requirements based on demand trends.

- Minimize storage costs by maintaining optimal inventory levels.

4. Risk Mitigation

- Use AI to identify potential disruptions, such as weather conditions or geopolitical events.

- Develop contingency plans to ensure operational continuity.

Case Study: Transforming a Logistics Company with AI

Background

A regional logistics company struggled with rising costs, frequent delivery delays, and customer complaints. They turned to AI-driven predictive analytics to address these challenges.

Approach

Integrated AI-based predictive models for demand forecasting.

- Deployed real-time fleet monitoring systems.

- Implemented route optimization algorithms.

- Introduced dynamic pricing strategies.

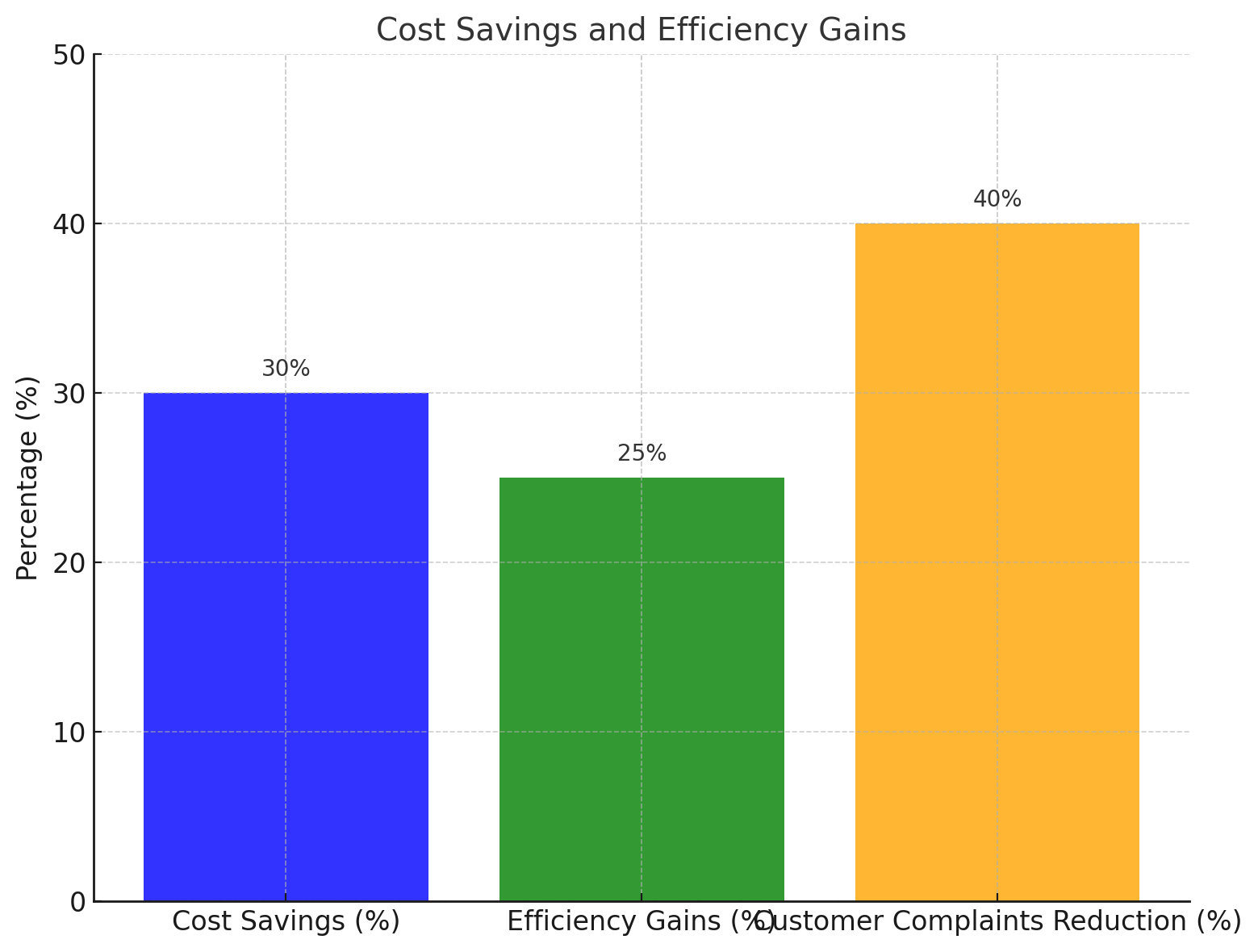

Result

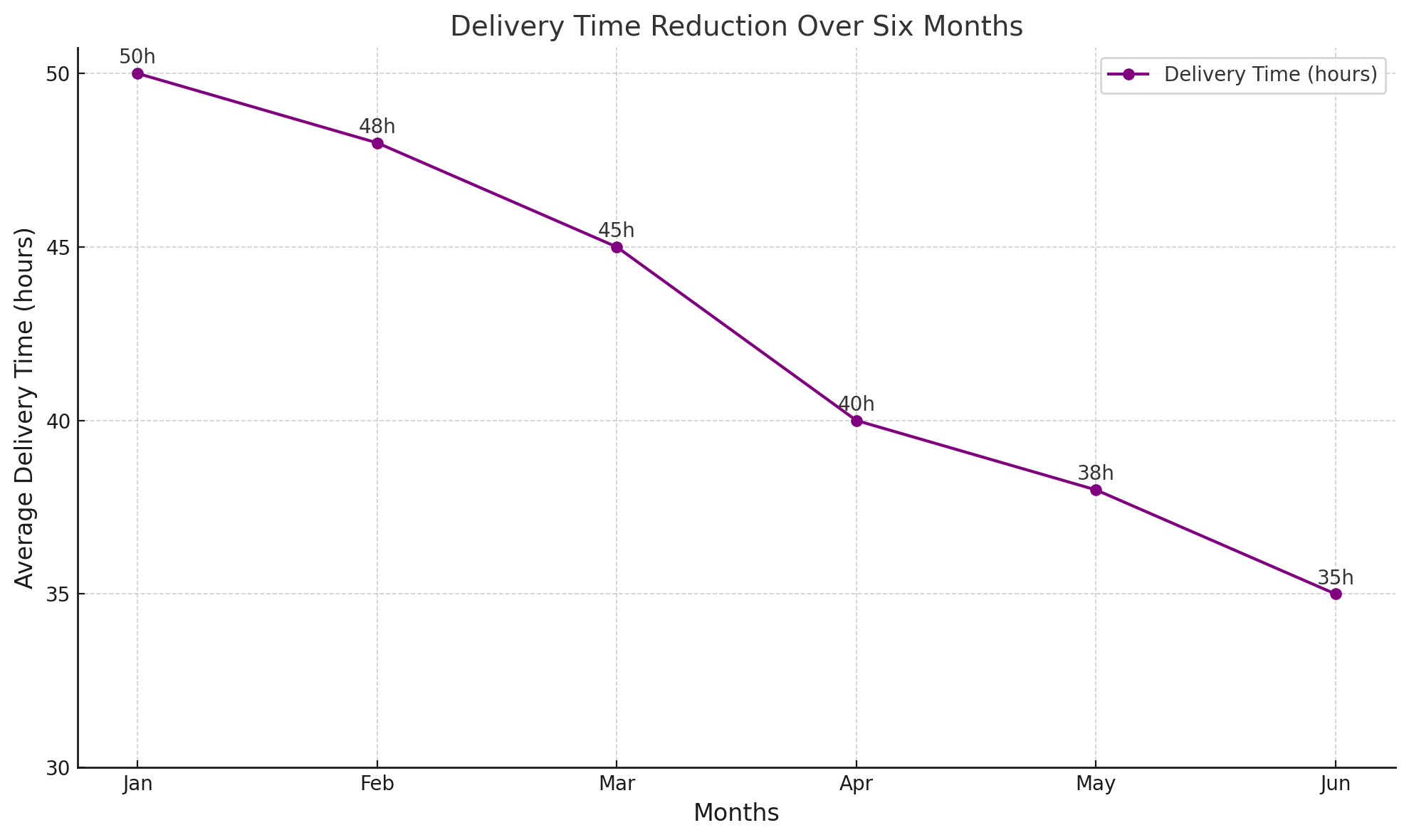

- Enhanced Efficiency: Delivery times improved by 25%.

- Cost Savings: Operational costs reduced by 30%.

- Customer Satisfaction: Complaints decreased by 40%.

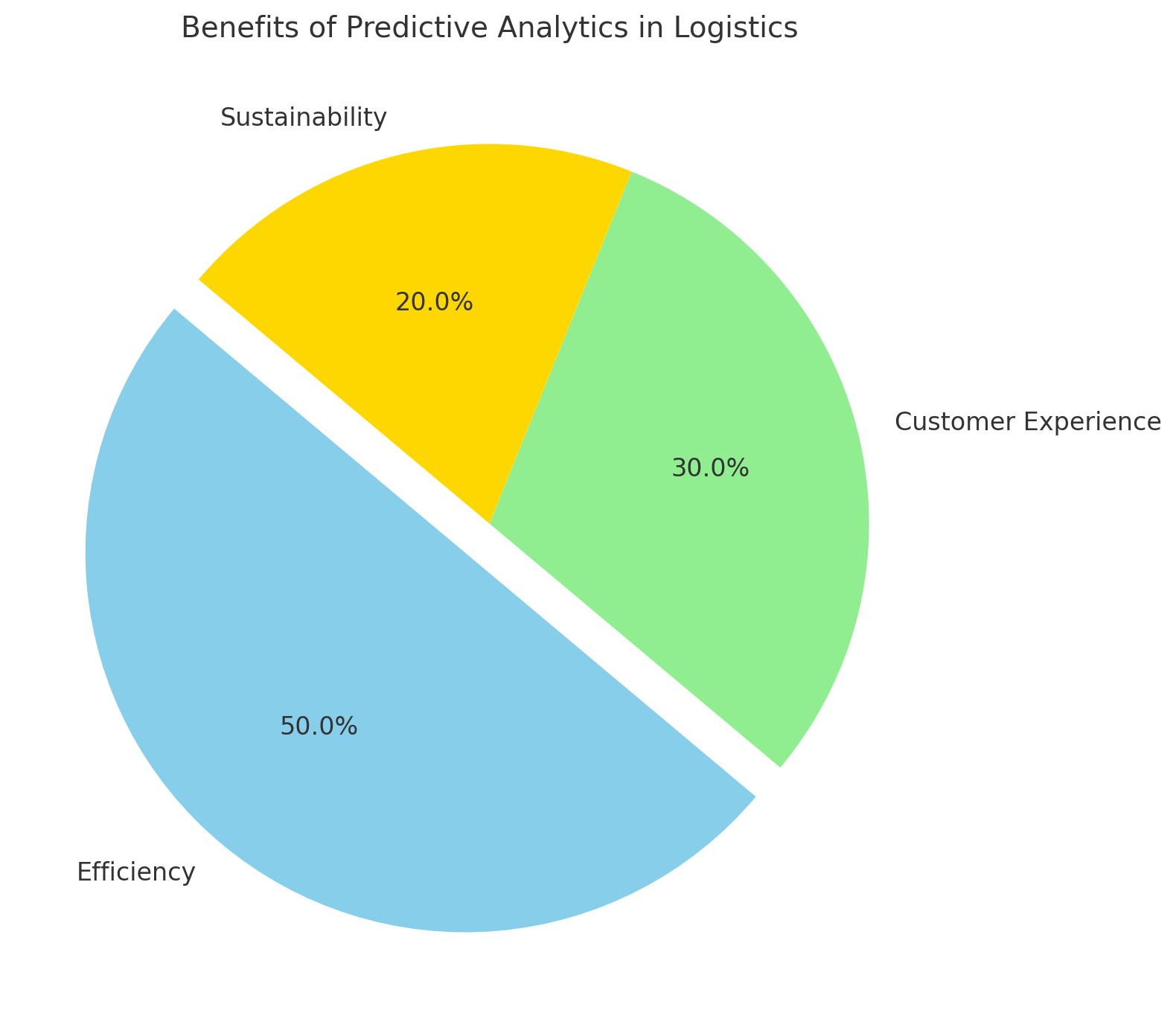

Measuring the Impact

1. Operational Efficiency

- Reduced idle time for vehicles and drivers.

- Improved resource utilization.

2. Customer Experience

- Real-time tracking and accurate delivery estimates enhanced satisfaction.

- Faster issue resolution through predictive insights.

3. Sustainability Goals

- Optimized routes reduced fuel consumption and carbon emissions.

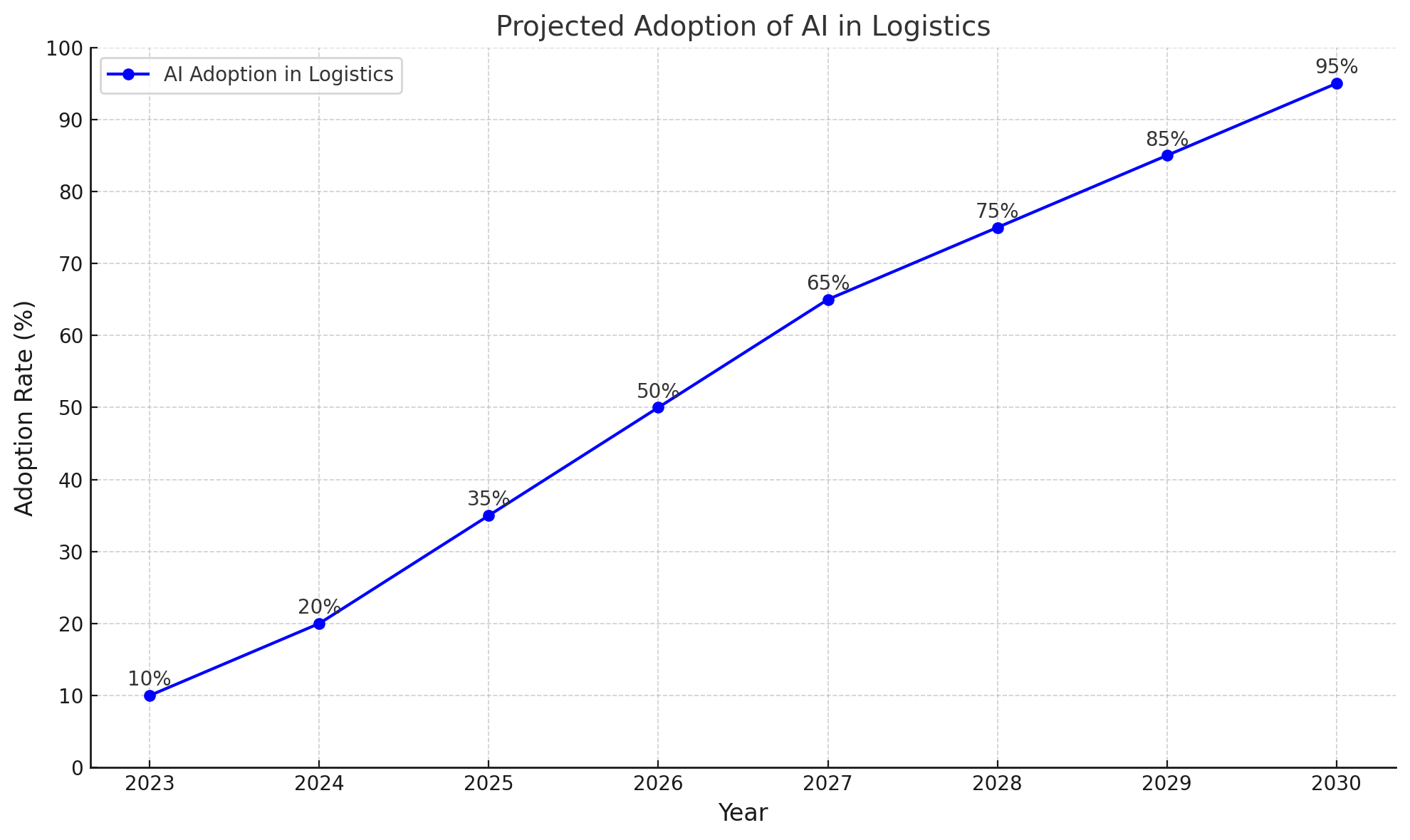

Future Trends in Logistics

1. AI-Powered Autonomous Vehicles

Self-driving trucks equipped with predictive models will revolutionize last-mile delivery.

2. Advanced Warehouse Automation

Predictive analytics will enhance robotics in sorting, packing, and inventory management.

3. Hyper-Personalized Delivery Experiences

AI will enable tailored delivery options based on customer preferences and historical behavior.

Best Practices for Implementation

1. Start with a Pilot Program

Test predictive analytics solutions on a smaller scale before full deployment.

2. Focus on Data Quality

Ensure accurate and comprehensive data collection for reliable predictions.

3. Train Your Team

Educate staff on how to use AI tools and interpret predictive insights.

4. Monitor and Refine

Continuously track performance metrics and refine models for better outcomes.

Conclusion

AI-driven predictive analytics is reshaping the logistics industry by enhancing efficiency, reducing costs, and improving customer satisfaction. As the demand for faster and more reliable deliveries grows, adopting these technologies will be essential for staying competitive. Logistics companies that embrace predictive analytics today will be well-positioned to lead the industry tomorrow.

FAQs

AI-driven predictive analytics uses advanced machine learning algorithms and data analysis to forecast future trends and events. For a logistics company, it can:

- Predict demand for goods and services.

- Optimize delivery routes.

- Reduce operational costs by improving resource allocation.

- Enhance customer satisfaction by providing accurate delivery timelines.

Predictive analytics relies on diverse datasets, including:

- Historical shipping and delivery data.

- Traffic patterns and real-time updates.

- Weather forecasts.

- Customer demand trends.

- Vehicle maintenance records.

- Inventory levels and warehouse data.

By combining these data sources, AI models can provide actionable insights to streamline operations.

Predictive analytics identifies the most efficient routes by:

- Analyzing historical traffic and delivery data.

- Incorporating real-time traffic updates and weather conditions.

- Factoring in delivery time windows and vehicle constraints. This helps reduce fuel consumption, delivery times, and overall operational costs.

Common challenges include

- Data integration: Aggregating data from multiple sources like GPS, CRM, and IoT devices.

- Model accuracy: Ensuring the predictive models are reliable and account for dynamic changes.

- Cost of adoption: Initial investment in AI tools and staff training can be high.

- Scalability: Ensuring the solution can handle growing data volumes and complexities as the business expands. Addressing these challenges requires a clear strategy and partnership with experienced AI solution providers.